As well as importing high quality equipment from overseas, Redlands has been directly involved in the design and manufacture of several locally produced items of specialised engine reconditioning equipment. Imported equipment must meet our stringent standards for quality and after sales service, while our involvement at all levels of design, production and support of the locally produced items ensures Redlands equipment is the best you can buy.

ShimMaster Shim Grinder | Australian designed and made Shim Grinder. Offers many benefits over cheaper imported models. More Info |

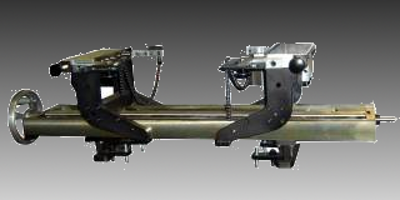

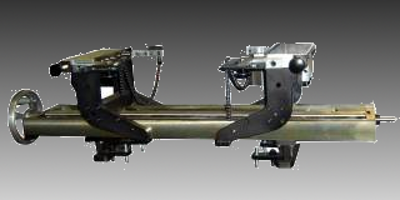

Winfield Jig | The ultimate in clamping cylinder heads for machining purposes. Mount cylinder heads for resurfacing in two minutes! More Info |

Micro-Vac Vacuum Tester | The Micro-Vac Vacuum Testing System offers a quick and easy check of cylinder heads for cracks and porosity without the hassle of bolting, clamping or submerging the cylinder head. More Info |

AIE Spray Parts Washer | AIE Spray Parts Washer

Proudly Australian made from high quality materials the AIE range of rotary parts washers are designed to clean grease and oil from aluminium, steel, brass, cast iron or plastics.

The AIE rotarty Parts Washer will save you TIME, MONEY and LABOUR, eliminating the use of dangerous and costly solvents.

AIE industrial parts washers are insulated and constructed from stainless steel, with stainless steel pumps giving them a long lasting and economical to run. More Info |

Lectromax Crack Detectors | Lectromax magnetic crack detection equipment offers accurate, reliable crack detection at economical prices. Electro-magnets, blacklights and consumables are all available. More Info |

Torque Plates | More details will be added soon More Info |